Essential Diagnostic Tools for Troubleshooting Gas Furnaces

Championing Furnace Fixes: Top Tools for Gas Giggles

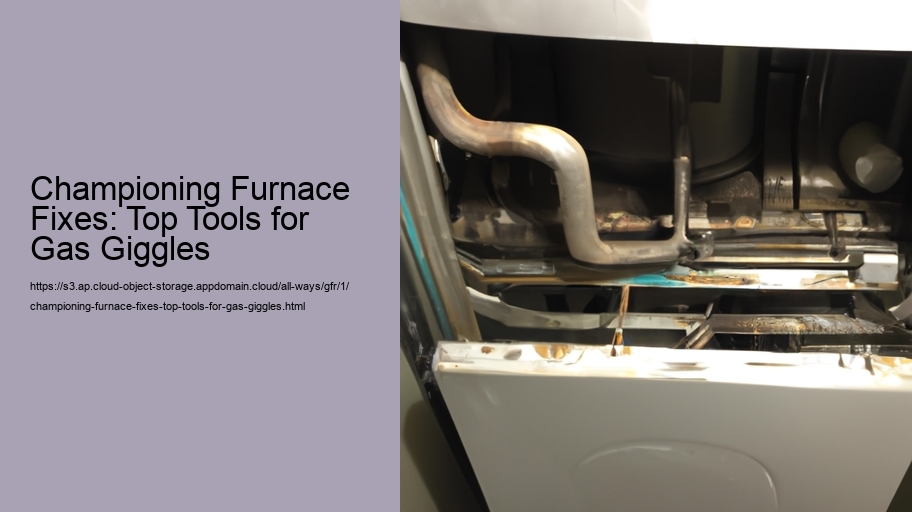

When the chill of winter nips at our heels, a gas furnace stands as the bulwark against the cold. Call All-Ways Heating & A/C for gas furnace repair services in Everett. A reliable source of warmth and comfort, it's easy to forget this silent sentinel—that is until it falters. Troubleshooting a gas furnace can be like solving a complex puzzle, and having the right tools in your arsenal is crucial to becoming a champion of furnace fixes.

First and foremost, safety cannot be overstated when dealing with gas appliances. A combustible gas detector is an essential tool that sniffs out any leaky situations which could lead not only to system inefficiencies but also dangerous scenarios. Ensuring no flammable gases are present before starting work protects both technician and home alike.

A multimeter becomes your electronic eyes within the circuitry labyrinth of modern furnaces. This versatile instrument measures voltage, current, and resistance, helping you diagnose electrical issues from faulty ignitions to malfunctioning thermostats. Its probes can tease out secrets hidden in wires and components, revealing whether they sing with electricity or sit in sullen silence.

The humble manometer might not seem like much more than tubes and measurements but don't let its simplicity fool you; pressure differentials speak volumes about a furnace's health. Whether assessing gas pressure or air flow through vents, this tool ensures that pressures are within operational ranges—a critical factor for efficient combustion and heat exchange.

An inspection mirror paired with a sturdy flashlight allows you to peer into those dark corners where problems like cracks or blockages may lurk out of direct sight. Visual inspection is a fundamental step—catching physical faults early prevents minor issues from escalating into major malfunctions.

No troubleshooter's kit would be complete without hand tools such as wrenches, screwdrivers, pliers—and perhaps most importantly for furnaces—the nut driver set tailored for disassembling panels or securing components snugly back into place after repairs are made.

Moreover, thermocouple testers cater specifically to one of the most common fail points in gas furnaces: the thermocouple itself which acts as a safety device ensuring gas valves operate correctly. Testing this component can quickly determine if it’s responsible for keeping your fireplace cold despite all other systems being go.

Lastly, an infrared thermometer offers instant temperature readings from afar—helpful not just during diagnostics but also when verifying that repaired areas come up to expected warmth without having to touch potentially hot surfaces directly.

Armed with these tools—and knowledge—an adept technician can tackle nearly every challenge a mischievous furnace might throw their way. No longer will homeowners dread the 'gas giggles' of an unruly heating system; instead they'll rest easy knowing there are champions equipped with essential diagnostic tools ready to bring back the heat.

Must-Have Mechanical Tools for Effective Furnace Repairs

Championing Furnace Fixes: Top Tools for Gas Giggles

When the cold grip of winter tightens its hold, the last thing anyone wants is a fickle furnace. To keep this essential home appliance humming happily through the frigid months, a set of specialized mechanical tools is indispensable for any repair professional or DIY enthusiast looking to tackle furnace repairs effectively.

First and foremost, an accurate multimeter is a must-have in your toolkit. This versatile device allows you to diagnose electrical issues by measuring voltage, current, and resistance. Whether it's troubleshooting thermostat problems or ensuring that the igniter gets the right amount of electricity, a multimeter is your electronic whisperer in deciphering hidden electrical tales.

Wrenches and screwdrivers are the unsung heroes of any tool collection. A variety of sizes and types (including adjustable wrenches and insulated screwdriver sets) ensure that you can tackle nuts, bolts, and screws with precision. They're like keys to a kingdom of components waiting within the metal casing of your furnace.

Another key player in your arsenal should be a high-quality pipe wrench. Gas furnaces have gas lines that require careful handling; tightening and loosening these connections without damaging them calls for a sturdy pipe wrench that provides ample leverage and grip.

A telescoping magnetic tool is another clever addition. When working in cramped spaces where screws may fall into tight corners or crevices, this tool can be an absolute savior—retrieving lost metallic pieces with its magnetic tip ensures that small setbacks don't turn into major headaches.

Don't overlook the need for good lighting—a durable headlamp or work light illuminates dark nooks inside cabinets or behind appliances so you can spot signs of wear-and-tear or pinpoint areas requiring attention.

programmable thermostat installation

For ductwork adjustments and repairs, tin snips are invaluable. These allow you to cut through metal with ease when installing new vents or repairing existing ones – making sure heated air flows exactly where it should.

A combustion analyzer comes next on our list; this sophisticated gadget measures gases like carbon monoxide produced by your gas furnace. It's crucial for verifying safe operation levels as well as optimizing fuel efficiency – breathing easy knowing your furnace isn't just fixed but also fine-tuned for performance.

Finally, one should never underestimate the importance of safety equipment such as gloves and goggles. Protecting yourself against sharp edges, hot surfaces, chemicals, and particulates ensures that fixing furnaces remains not only effective but also safe.

In conclusion, equipping yourself with these essential mechanical tools transforms daunting furnace disorders into manageable tasks—or 'gas giggles', if you will—allowing both professionals and do-it-yourselfers to champion over their heating systems' hiccups with confidence throughout those long winter months.

Safety Equipment and Gear for Protecting Yourself During Fixes

When it comes to championing furnace fixes and ensuring your safety while dealing with gas appliances, the correct safety equipment and gear are non-negotiable. Whether you're a seasoned technician or a homeowner looking to perform minor maintenance, understanding the importance of protective tools cannot be overstated – after all, when working with gas furnaces, the stakes are quite literally as high as they can get.

To start with, personal protective equipment (PPE) is essential. This includes items such as safety goggles or glasses to protect your eyes from any debris that could result from repairs. Dust and metal shavings can cause severe damage to the eyes, so this protection is critical. Additionally, wearing sturdy work gloves will safeguard your hands against cuts from sharp edges and provide some defense against burns.

Another crucial piece of gear is a good quality respirator or mask. When you're dealing with gas giggles – slang for inadvertent exposure to small amounts of natural gas – inhaling fumes can be hazardous. A respirator ensures that you're not taking in harmful chemicals or dust particles that might lead to respiratory issues.

Moreover, flame-resistant clothing can add an extra layer of security. While not always necessary for minor fixes, if you're engaging in more intensive repairs where there's even a slight risk of fire or explosion due to gas leaks, wearing materials that won't easily ignite could be life-saving.

A gas detector should also be part of your arsenal. Before starting any repair work on a furnace, checking for leaks is imperative; otherwise, you could find yourself in an explosive situation. These detectors will alert you to the presence of combustible gases at levels well below what would be immediately dangerous but still require caution and remediation.

Furthermore, proper footwear is vital – shoes with slip-resistant soles ensure stability as you work around the furnace area which might have slick surfaces due to dust or spilled liquids.

An often-overlooked but equally important tool is knowledge: understanding how your furnace works and recognizing signs of potential danger are invaluable assets in protecting yourself during fixes.

Lastly, never underestimate the power of common sense when using safety equipment and gear. Regular checks on their condition make sure they provide maximum protection; worn-out gloves or cracked goggles need replacement without delay.

In conclusion, equipping yourself with appropriate safety gear before embarking on any furnace repairs does much more than just mitigate risks—it provides peace of mind allowing for focus and precision during troubleshooting and repairing tasks while also respecting the potent forces at play when working with gas appliances. Championing these practices ensures that ‘gas giggles’ remain a lighthearted term rather than an ominous reality.

Advanced Instruments for Fine-Tuning and Calibration of Gas Furnaces

Championing Furnace Fixes: Top Tools for Gas Giggles

When it comes to maintaining the peak performance of gas furnaces, the devil is often in the details. It's not just about making sure the unit turns on and off; it's about ensuring that every component works in harmony, delivering heat efficiently and safely to our homes. This is where advanced instruments for fine-tuning and calibration come into play, acting as both the scalpel and stethoscope of HVAC professionals.

Imagine a furnace as an orchestra, with each part carefully playing its tune. If one instrument—the blower motor, say—is out of sync, it can throw off the entire performance. Advanced tools are like having a master conductor at hand who can hear that off note and bring everything back into perfect harmony.

One such indispensable tool is a combustion analyzer. This device measures gases like carbon monoxide, oxygen, and nitrogen oxides emitted by the furnace—a critical aspect considering these gases' implications on efficiency and safety. By reading these levels precisely, technicians can adjust burners for optimal combustion—akin to tuning a guitar to ensure each strum resonates with clarity.

Infrared thermometers are also part of this elite set. They allow techs to take surface temperature readings from a distance—vital when assessing parts that should not be touched due to their high temperatures or inaccessibility. This non-contact approach ensures accuracy without risking damage or injury—a prudent measure akin to testing waters before diving in.

Then there’s the manometer—a tool essential for verifying proper gas pressure. It's like checking tire pressure; too low or too high can lead to inefficiency or even danger. A manometer provides exact readings so adjustments can be made with precision, ensuring your furnace isn’t overexerting itself or operating lethargically.

We mustn't forget about electronic leak detectors either; they sniff out any breaches where gas might escape unnoticed—small fissures that could grow into larger problems if left unchecked. These devices are sensitive enough to detect even minor leaks early on providing an opportunity for preemptive action before issues escalate into full-blown breakdowns—or worse yet—hazards.

And for truly sophisticated diagnostics, thermal imaging cameras can visualize heat distribution within a system revealing areas where insulation may be lacking or airflow is restricted—an insight no mere guesswork could match.

These advanced instruments represent more than just gadgets—they embody the meticulous care required for fine-tuning gas furnaces effectively. With them at their disposal, technicians transform from mere repairmen into maestros of maintenance orchestrating each repair with expertise crafted through technology's lens.

So while we may chuckle at the thought of 'gas giggles,' let's not underestimate what it takes to keep those laughs warm through winter nights: An arsenal of refined tools wielded by skilled hands ever ready to champion furnace fixes with finesse beyond compare.

Smart Devices and Apps to Enhance Furnace Repair Efficiency

The advent of smart devices and apps has revolutionized numerous industries, and the domain of furnace repair is no exception. With a wave of technological advancements at their fingertips, technicians are now more equipped than ever to champion furnace fixes with an efficiency that was once unthinkable. These top tools not only streamline the diagnostic process but also ensure precise repairs, often transforming tedious tasks into what could be described as "gas giggles" for the tech-savvy professional.

Smart thermostats are prime examples of such devices. They serve as the front line in diagnostics by continuously monitoring furnace performance and alerting homeowners and service professionals to irregularities before they evolve into costly problems. Their ability to connect to Wi-Fi enables remote troubleshooting which can sometimes allow technicians to resolve issues without even setting foot in a home.

Moreover, infrared thermal cameras have become indispensable tools in a technician's arsenal. When paired with a smartphone or tablet, these cameras can detect subtle differences in heat patterns, pinpointing areas where insulation may be lacking or where there might be leaks within the system.

Championing Furnace Fixes: Top Tools for Gas Giggles - exhaust flue checking

- gas valve replacement

- condensate drain cleaning

Apps specifically designed for HVAC professionals have transformed smartphones into powerful diagnostic computers capable of interfacing with modern furnaces through wireless connections. They can analyze data, suggest solutions based on error codes and provide step-by-step guides for complex repairs. Such apps often come with customer management features too, enabling technicians to schedule appointments, process payments, and maintain detailed service records all from one device.

In addition to diagnostics and repairs, smart devices play a significant role in preventive maintenance. Sensors attached to different parts of the furnace system can send real-time data about its condition directly to an app on a technician’s phone or tablet. Predictive analytics algorithms then assess this data stream to forecast potential failures before they happen.

Lastly, augmented reality (AR) is starting to make its mark on furnace repair by providing immersive training experiences for technicians who are learning their trade or seasoned pros brushing up on new technology. AR headsets can overlay digital information onto physical components being worked on—guiding through repairs with interactive 3D diagrams and instructional videos.

In conclusion, smart devices and applications have empowered furnace repair experts like never before—enhancing efficiency through improved diagnosis accuracy, predictive maintenance capabilities, streamlined workflow processes and innovative training methods—all leading towards quicker fixes that leave customers warm and satisfied while giving technicians something to smile about amidst their daily rounds of gas giggles.

Organizational Aids to Keep Your Toolkit Streamlined and Ready

Championing Furnace Fixes: Top Tools for Gas Giggles

In the world of home heating and repair, there’s a special kind of satisfaction that comes from conquering furnace malfunctions. These intricate systems are the heartbeats of warm homes during cold seasons, and when they start to show signs of distress—unusual noises, inconsistent heating, or complete breakdowns—it's time for the repair champions to step in. blower motor repair But even heroes need their trusty sidekicks; in this case, it's not a loyal steed but a well-organized toolkit equipped with top-notch tools that make those gas giggles a thing of the past.

The first step in ensuring you're ready to tackle any furnace issue is maintaining an organized toolkit. This doesn't just mean having all your tools in one place—it means having them easily accessible and in good working order. Organizational aids such as toolboxes with dedicated compartments, magnetic tool racks, and portable caddies can be invaluable. They keep your wrenches from getting cozy with your screwdrivers and help avoid the frustration of digging through a jumbled mess to find the right socket.

Once organization is mastered, let’s look at some essential tools that every furnace fixer should have on hand:

1. Multimeter – This versatile instrument is indispensable for diagnosing electrical problems within a furnace system. Whether checking continuity or measuring voltage differences, a reliable multimeter ensures you’re not operating blind when it comes to wiring issues.

2. Adjustable Wrenches – A set of these will allow you to grip onto various sizes of nuts and bolts which are common components within furnace designs.

3. Nut Drivers – Precise control over smaller fasteners is critical when dealing with delicate parts or tight spaces often encountered in furnace repairs.

4. Manifold Gauge Set – For those dabbling in HVAC systems as well, this tool helps technicians diagnose refrigerant levels and pressure issues—all part of ensuring efficient furnace operation.

5. Inspection Camera – Sometimes problems hide out of plain sight inside ducts or behind panels; an inspection camera can peek into these nooks and crannies saving time and preventing unnecessary disassembly.

6. Flashlight & Headlamp – Good lighting is non-negotiable when peering into the dimly lit recesses where many furnace components reside.

7. Leak Detector – When fixing furnaces that use natural gas or other combustibles, detecting leaks quickly can prevent hazards—making this tool vital for both safety and functionality checks.

8. High-Temperature Sealants & Tapes – These specialized materials ensure secure seals around joints and seams subjected to high heat conditions found near furnaces.

9. Cordless Drill/Driver – A robust battery-powered drill/driver will speed up disassembly while also serving as an efficient way to drive screws tightly back into place during reassembly.

10.Thermocouple Tester - As thermocouples are crucial for safety mechanisms in gas furnaces by sensing temperatures accurately determining their integrity becomes important.

Having these tools neatly arranged within reach means less downtime rummaging through gear which translates directly into more effective troubleshooting sessions—and who doesn’t want fewer delays when battling winter chills?

Just like knights require armor before heading into battle, championing successful fixes starts long before you open up any panels or inspect pilot lights; it begins with foresightful preparation grounded in thoughtful organization complemented by quality equipment tailored specifically for heating system challenges

So next time your gas-fueled guardian starts acting up remember that victory lies